Hello, welcome to Dalian Kaide Precision Machinery Co., Ltd!

Dalian Kaiman Technology Co., Ltd

Dalian Kaide Precision Machinery Co., Ltd

Contacts:Sun Zong

Mob:+86-13555929577

Tel:+86-0411-88026630

Email:dlkdjmjx@163.com

URL:www.dl-kd.com

Add:Fuquan Construction Group Hospital, Zhanqian street, Jinzhou District, Dalian

Dalian automotive parts processing is a crucial part of the automotive manufacturing process, directly related to the performance, safety, and service life of automobiles. With the rapid development of the automotive industry, component processing technology is also constantly advancing, from traditional manual operations to modern automated production, and the level of refinement and intelligence in processing technology is constantly improving.

1、 The main processes of automotive parts processing

Casting process

Casting is one of the commonly used processes in the processing of automotive components, especially in the manufacturing of large and complex parts such as engine cylinder blocks, cylinder heads, and gearbox housings. The casting process involves pouring molten metal into a mold and cooling it to form the desired shape. Common casting methods include sand casting, die-casting, gravity casting, etc. Among them, die casting is widely used in the production of aluminum alloy components due to its high production efficiency and good surface quality.

forging process

Forging is a process of obtaining the desired shape and properties by applying pressure to metal materials to induce plastic deformation. Forging technology is commonly used to manufacture high-strength and high toughness components, such as crankshafts, connecting rods, gears, etc. Forging is divided into two types: free forging and die forging. Die forging is more widely used in automotive parts processing due to its high precision and efficiency.

stamping

Stamping technology is mainly used for producing body coverings and structural components, such as doors, engine covers, chassis, etc. Stamping process involves punching, bending, stretching and other operations on metal sheets through molds to form the desired shape. Stamping technology has the advantages of high production efficiency, low cost, and stable quality, and is one of the indispensable processes in automobile manufacturing.

machining

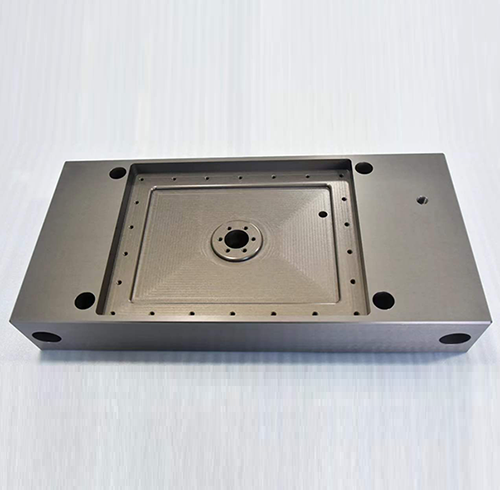

Mechanical processing is the precise machining of metal materials through operations such as turning, milling, drilling, and grinding to achieve the required dimensions and shapes for design. Mechanical processing is commonly used to produce high-precision components such as engine pistons, bearings, gears, etc. With the popularization of CNC machine tools, the accuracy and efficiency of mechanical processing have been greatly improved.

procedure

The welding process is to connect two or more metal parts together by heating or applying pressure. In automobile manufacturing, welding technology is widely used in the manufacturing of body structures, chassis, exhaust pipes and other components. Common welding methods include arc welding, gas shielded welding, laser welding, etc. The welding quality directly affects the strength and durability of the components, so the control of the welding process is crucial.

Surface treatment process

The surface treatment process is aimed at improving the corrosion resistance, wear resistance, and aesthetics of components. Common surface treatment methods include electroplating, spraying, heat treatment, etc. For example, engine pistons usually require surface hardening treatment to improve their wear resistance; The exterior covering of the vehicle needs to be sprayed to improve its corrosion resistance and aesthetics.

2、 Key Technologies for Automotive Parts Processing

NUMERICAL CONTROL

Numerical Control (CNC) technology is one of the core technologies in automotive parts processing. Through CNC machine tools, high-precision machining of complex shaped components can be achieved. Numerical control technology not only improves machining accuracy, but also greatly enhances production efficiency and reduces human errors. With the popularization of five axis CNC machine tools, the machining of complex surfaces has become easier.

intelligent manufacturing technology

Intelligent manufacturing technology is the development direction of future automotive parts processing. By introducing technologies such as industrial robots, automated production lines, and the Internet of Things (IoT), the automation and intelligence of the production process can be achieved. Intelligent manufacturing technology not only improves production efficiency, but also reduces production costs and improves product quality.

Materials Technology

With the advancement of the trend towards lightweighting in automobiles, the application of new materials in the processing of automotive parts is becoming increasingly widespread. For example, lightweight materials such as aluminum alloys, magnesium alloys, and carbon fiber composites are widely used in the manufacturing of components such as car bodies and engines. The use of new materials not only reduces the weight of cars, but also improves fuel economy and environmental performance.

Simulation and Optimization Technology

Simulation and optimization technology have played an important role in the processing of automotive parts. Through computer-aided design (CAD) and computer-aided engineering (CAE) technologies, the performance of components can be simulated and analyzed during the design phase, design parameters can be optimized, trial production times can be reduced, and development costs can be lowered. For example, finite element analysis (FEA) can predict the deformation and stress distribution of components under stress, thereby optimizing structural design.

Automotive parts processing is the core link in automobile manufacturing, and its technological level directly affects the performance and quality of automobiles. With the continuous advancement of technology, the processing technology of automotive parts is also constantly innovating and developing. In the future, lightweight, intelligent, customized, and green manufacturing will become the main development directions for automotive parts processing. By continuously optimizing processing techniques and introducing advanced technologies, automotive parts processing will usher in broader development prospects, providing strong support for the sustainable development of the automotive industry.

Focus on us

National consultation hotline:

+86-0411-88026630

Tel:+86-13555929577

Email:dlkdjmjx@163.com

Add:Fuquan Construction Group Hospital, Zhanqian street, Jinzhou District, Dalian